Advantages and disadvantages of vacuum circuit breakers

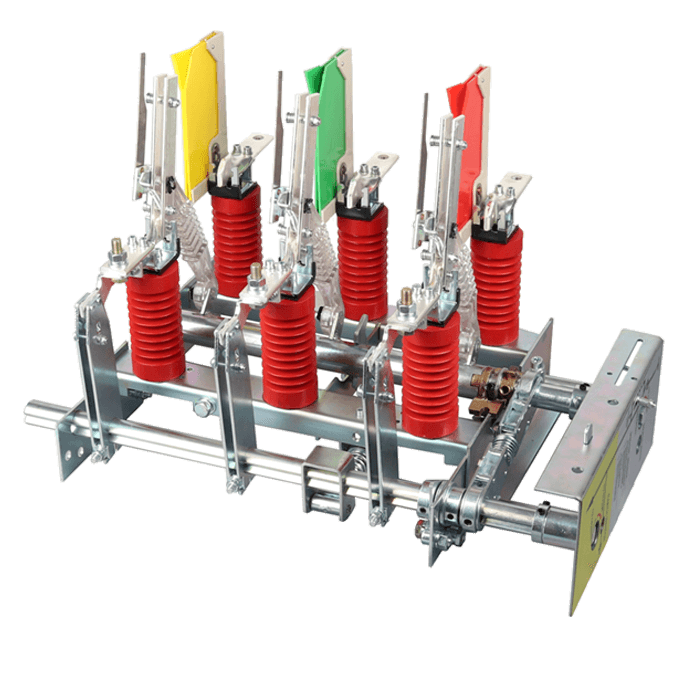

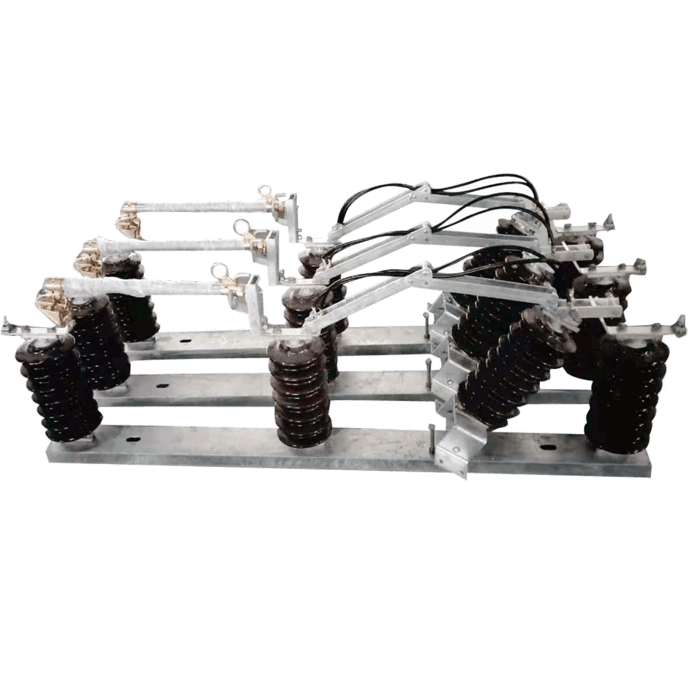

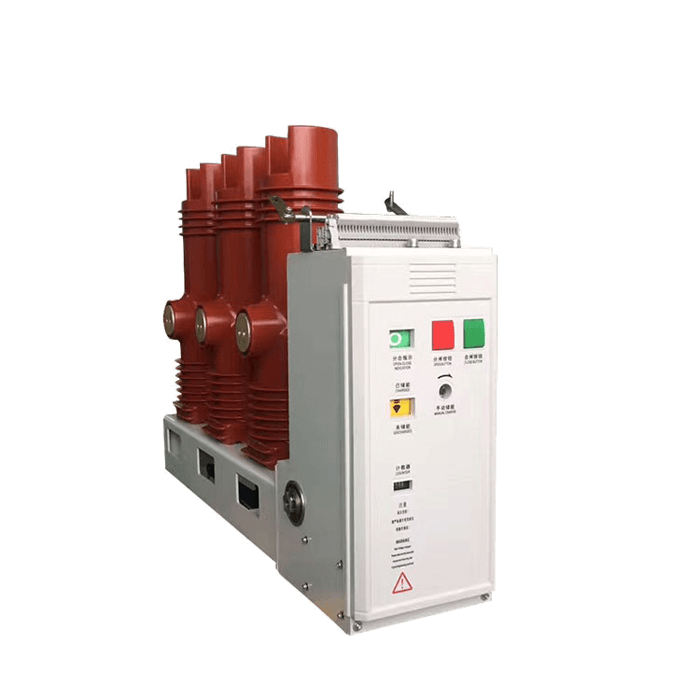

Vacuum is mostly used in high-voltage switch cabinets, and refers to circuit breakers that use vacuum as an arc extinguishing and insulating medium to perform current switching and closing in a vacuum container. Since its introduction in the early 1960s, with the improvement of various key processes and the development of new arc extinguishing chambers and operating mechanisms, the technical parameters of vacuum circuit breakers have been continuously improved, and they have been rapidly obtained with excellent performance and outstanding advantages. With the development of high-voltage switchgear, the application in high-voltage switchgear is also more and more extensive.

It is precisely because of some advantages of vacuum circuit breakers that the application rate in high-voltage switchgear is so high. Today, Zhejiang JGGY electrical manufacturer will give you a detailed introduction to the advantages and disadvantages of vacuum circuit breakers.

Advantages of vacuum circuit breakers:

1. The arc is extinguished in a sealed container, and the arc and hot gas are not exposed. As a separate component, the arc extinguishing chamber is simple and convenient to install and debug.

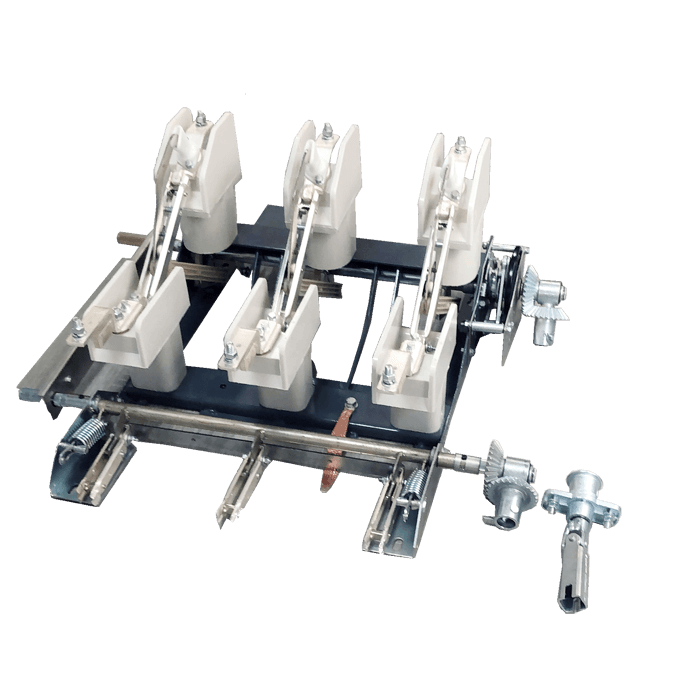

2. The contact gap is very small, generally about 10mm, the closing power is small, the mechanism is simple, and the service life is long.

3. The arc extinguishing time is short, the arc voltage is low, the arc energy is small, the contact loss is small, and the breaking times are many.

4. The inertia of the moving guide rod is small and can be used frequently.

5. The operating mechanism is small, the whole machine is small in size and light in weight.

6. The control power is small, and the action noise is small when the switch is operated.

7. The arc extinguishing medium or insulating medium does not need oil, there is no danger of life and explosion, and it is safe.

8. The contact head is divided into a completely sealed structure, which will not be affected by moisture, dust, harmful gases, etc. to reduce its performance. Reliable work, stable on-off performance.

9. After the arc is broken, the medium between the fractures recovers quickly, and the medium does not need to be replaced.

10. The ring does not age and does not need to be replaced. During the service life, the contact part does not need to be repaired or inspected. Generally, it can be up to about 20 years without maintenance. The maintenance workload is small and the maintenance cost is low, which is only about 1/20 of the oil-less circuit breaker.

11. It has the function of multiple reclosing, which is suitable for the application requirements of the distribution network.

What are the disadvantages of vacuum circuit breakers:

1. When switching inductive or capacitive loads, it is easy to cause over-voltage due to current cut-off, legitimate, re-ignition and other reasons, and corresponding over-voltage protection should be adopted.

2. The high investment price of the product is mainly determined by the professional production of the vacuum interrupter and the reliability of the mechanism. If the operation and maintenance costs are comprehensively considered, the price is not high.

3. Since the contact structure of the vacuum circuit breaker is of the docking type, and the operating mechanism uses a spring, it is easy to produce closing bounce and opening bounce. Closing bounce will not only produce a high overvoltage and affect the stable operation of the power grid, but also cause the contacts to burn out or even weld, especially when the input device group generates inrush current and short-circuit closing. The opening rebound will reduce the contact distance after the arc, resulting in heavy breakdown after the arc, and the consequences are very serious.

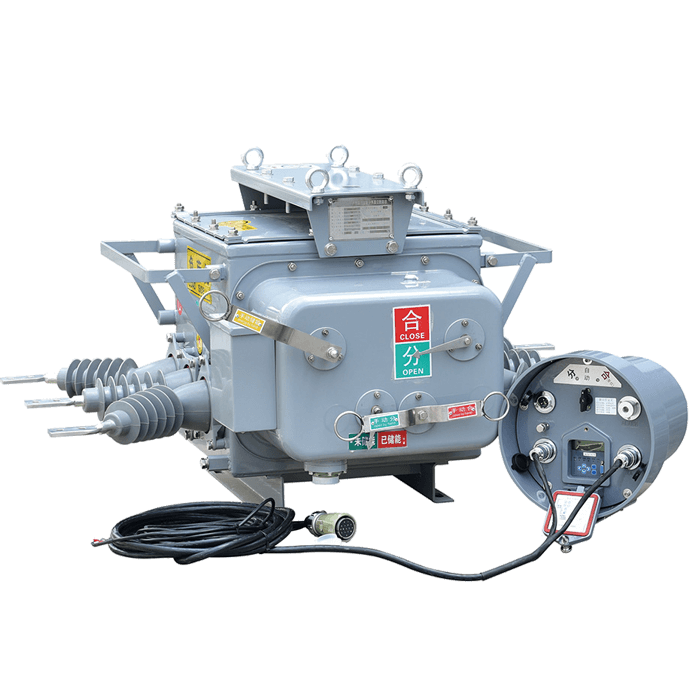

The vacuum circuit breakers generally used in high-voltage switchgear belong to indoor vacuum circuit breakers, such as the vacuum circuit breaker used in 12KV 24KV 36KV VS1 mid-mounted high-voltage switchgear