High voltage load break switch installation requirements

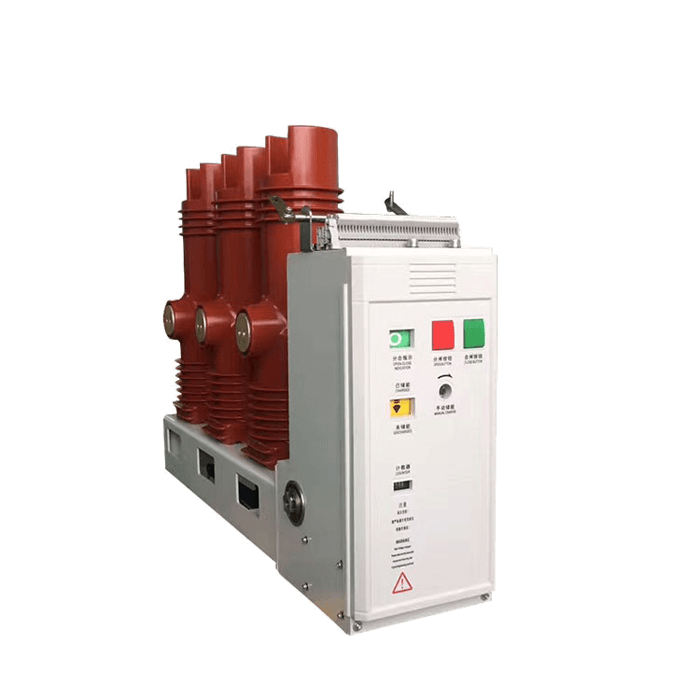

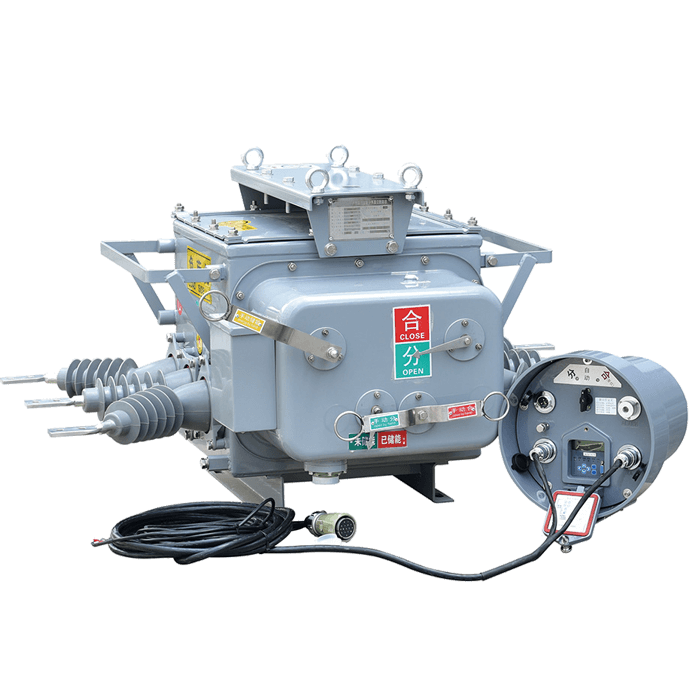

The high-voltage load switch is an electrical appliance whose function is between the high-voltage circuit breaker and the high-voltage isolation switch. The high-voltage load switch is often used in series with the high-voltage fuse. Used to control power transformers. The high-voltage load switch has a simple arc extinguishing device, because it can switch on and off a certain load current and overload current. However, it cannot disconnect the short-circuit current, so it is generally used in series with a high-voltage fuse for short-circuit protection.

The installation requirements are:

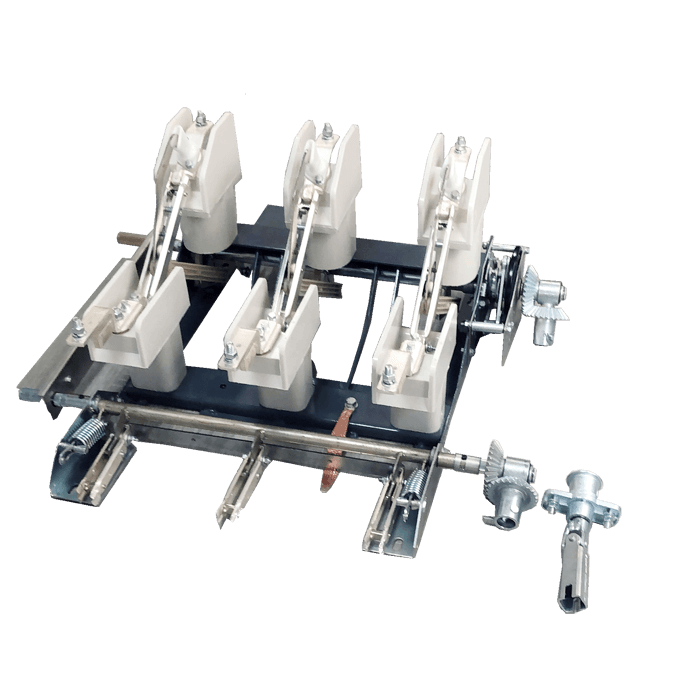

1. The blade of the load switch should be aligned with the fixed contact and make good contact;

2. The blades of each phase of the 10kV high-voltage load switch should be in contact with the fixed contacts at the same time, and the difference between the front and rear should not be greater than 3 mm;

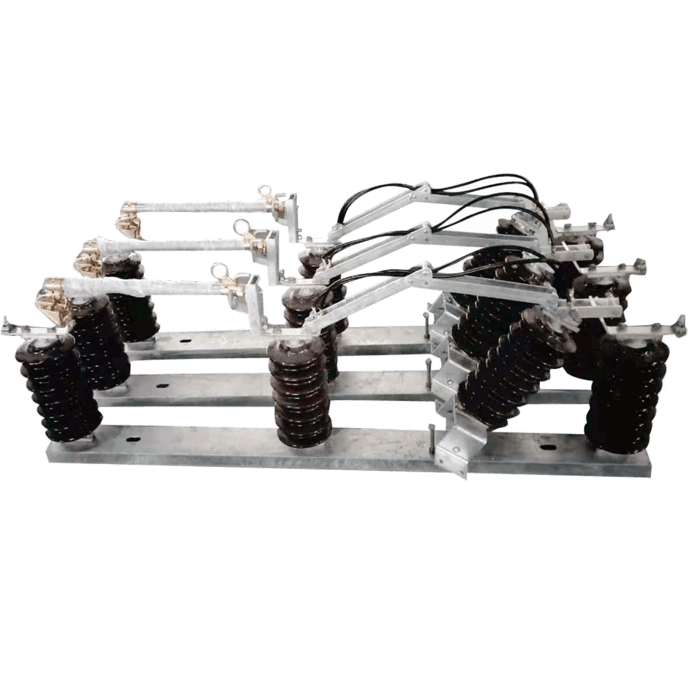

3. The pulling distance of the load switch on the outdoor high-voltage column should be greater than 175 mm; the pulling distance of the indoor compressed air load switch should be 182+3 mm;

4. The fixed contact of the load switch is generally connected to the power supply side. When installed vertically, the fixed contacts are on the upper side;

5. The transmission parts of the load switch should be free of cracks and damage, the action should be flexible, and the tie rod should be equipped with a protective ring (sleeve);

6. The transmission parts such as the extension shaft, bearing, coupling and crank of the load switch should have sufficient mechanical strength, and the pin of the connecting rod shaft should not be welded dead;

7. The connection between the load switch installed on the wall and the incoming cable should go through the busbar;

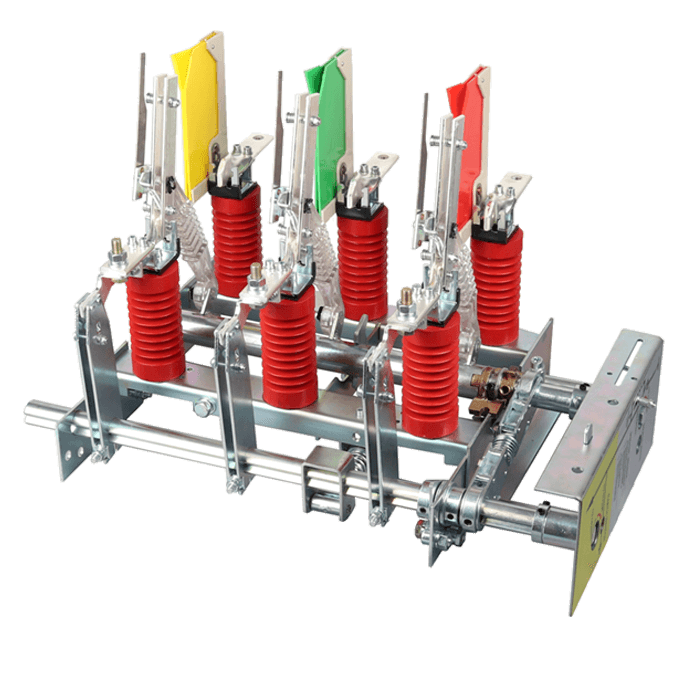

Inside MV LBS, 12KV, 24KV, FN7; Outside LBS, FZW32, SF6 LBS